Welding Fixture

Our goal is to become your true partner in the field of welding fixture China. GUANGDONG SUNYUU TECH CO.,LTD is a high-tech enterprise dedicated to the development, design and manufacture of checking fixture for automotive industry. We aim to offer our customers perfect engineer& technical solutions. The price is competitive and the product is quality-assured, which is a good choice for your long-term cooperation.

Product Application

Our company's main products include automotive sheet metal parts inspection fixtures, plastic parts inspection fixtures, assembly parts inspection fixtures, cubic fixtures, etc. The products are widely used in automobile manufacturing, aerospace parts inspection, medical device manufacturing, injection molding and other industries.

Our Team

The company has been established for more than 10 years and has an experienced team of professionals who are knowledgeable in their respective fields.

Our Services

The company has a professional sales team to provide you with high-quality pre-sales consulting services. During the order production process, customers can communicate with us at any time to understand the production progress. At the same time, we provide high-quality after-sales service to meet the different needs of customers.

Customizable Solutions

We understand that different customers have different needs, and we provide customizable solutions to meet these needs. We have a team of experts who can work with customers to design and manufacture products that meet specific requirements.

-

Car Stamping Parts checking fixture

1,Very beautiful appearance Automotive checking fixture 2, Very precise accuracy 2.1 Datum'sAdd to Inquiry -

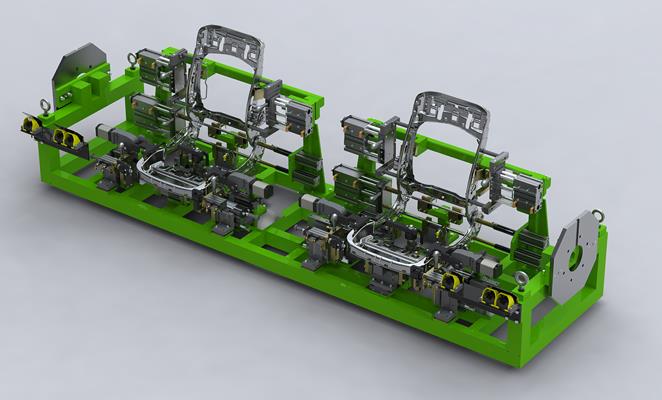

Robotic Welding Fixture Line

If you are going to check the quotation of robotic welding fixture line made in China from one ofAdd to Inquiry -

Auto Pillar Parts Welding Fixture

If you are going to check the quotation of auto pillar parts welding fixture made in China from oneAdd to Inquiry -

Front Bumper Welding Fixture

If you are going to check the quotation of front bumper welding fixture made in China from one ofAdd to Inquiry -

Automotive Seat Welding Fixture

If you are going to check the quotation of automotive seat welding fixture made in China from oneAdd to Inquiry

Advantages of Welding Fixture

Improved weld quality

Welding fixtures that are precision-made produce consistent welds of high quality. This consistency is essential in applications where weld integrity can impact performance and safety. Fixtures reduce defects by ensuring correct alignment and positioning.

Increased production efficiency

Welding fixtures simplify production by allowing for faster assembly and reducing the time required to complete each welding. The increased efficiency allows for a higher production volume, which can quickly meet customers’ needs. Automating some welding tasks increases productivity and frees up skilled workers to perform more complex operations.

Increased worker safety

Welding fixtures can also make a workplace safer. They reduce the risks of accidents due to misaligned or shifting components by securely holding them in place. Fixtures also reduce the amount of manual handling required during the welding process. They expose workers to less heat, sparks, and potentially dangerous materials.

Automotive Industry: In the automotive industry, precision is crucial. We use welding fixtures to manufacture various components, ranging from simple brackets to complex chassis pieces. We craft each piece to meet strict size, strength, and alignment specifications. This ensures the safety and performance of the vehicles.

Aerospace and Defense: Precision and reliability are essential in the aerospace and defense industry. Welding fixtures allow the production of critical parts with tight tolerances. This includes engine parts, airframe structures, and other components.

Construction and Infrastructure: In construction and infrastructure, welding fixtures fabricate steel beams, frameworks, and other structural components. These fixtures ensure the precise joining of elements while maintaining structural integrity and safety.

Types of Welding Fixture

Gas welding fixtures

Welding is done by burning fuel in the presence of oxygen which produces extremely high temperatures that melt the parts and join them during welding. In the case of gas welding, the heat loss should be minimum to avoid weld cracks.

Arc welding fixtures

The workpiece can react chemically with oxygen and nitrogen gases from the air at higher temperatures produced by the arc while welding. To prevent the part from reacting with air, a protective shielding gas is used around the welding area to minimise the exposure of the workpiece to the surroundings.

Resistance welding fixtures

The fixtures must be free of debris and flash for safe operation. There are various reasons for healing up of the fixture like inductance, insulation, weld flash and location. Even magnetic tooling causes similar issues.

Laser welding fixtures

Laser welding is known for its versatility and quickness in producing narrow, deep welds with a minimum distortion and heat input. It has gained much popularity among the parts that require little to no-post weld processing.

Whether you are working with steel or plastic, welding involves painstaking precision. We provides welding fixtures to keep your materials in place while you finish welding a joint or seam. Hold, position, and secure part orientation weld after weld.

Our welding fixtures come in aluminum, steel, cast urethane/epoxy, and additional resilient materials. We manufacture fixtures for all types of projects, from simple shapes to those that require complex CNC contour milling.

In addition to creating a fixture that suits your needs, we also offer clamping/ejection and vacuum/expansion mechanisms. These are available in pneumatic and manual configurations to best serve your parts and welding setup.

Precautions for Use Welding Fixture

Material compatibility

It is essential to choose suitable materials for the fixture and the workpiece. The material of the fixture must be compatible with that of the workpiece to avoid contamination. Still, it must also withstand the stresses and strains during the welding process.

Welding access and visibility

Well-designed fixtures allow for easy access to the area of the joint for welding while also providing clear visibility for the operator and welding equipment. Technicians will perform the weld accurately and efficiently, reducing the defect risk. We carefully plan the layout of the fixture.

Heat and spatter resistant

Welding produces significant heat and spatter, which can cause damage to fixtures over time. We select materials and coatings resistant to these elements in our design process. This ensures the fixtures retain their precision and functionality after many uses.

Installation Requirements of Welding Fixture

Positioning of workpieces consumes time. Thus arrangements have to be made for the quick positioning and removal of the work parts to save time and improve productivity. The design should consider the safety of the operator and the workpiece too. The surfaces of fixtures are to be made of hardened materials to resist wear but are tough enough to withstand the impact forces that occur during welding. Sufficient clearance is to be provided for the quick loading and unloading of the workpieces. The fixture should be rigid enough to absorb vibrations during welding so that it doesn’t cause unnecessary movements in the tool or workpiece.

|

Shipping |

By Ocean/by Air. |

|

Transport Package |

Crate/Pallet |

|

Selling Units |

Single item |

FAQ

If you are going to check the quotation of welding fixture made in China from one of the famous welding jig manufacturers and suppliers in China, It is always at your service.

Stamping Parts CMM Holding Fixture CMM manufacturers, Auto Lamp Checking Fixture suppliers, auto light parts checking fixture , Welding Fixture China , welding jig , welding jig suppliers , welding jig China , welding jig quotation